Innovating Cell Culture for a Sustainable Future

As scientists and innovators, we envision a future where scientific achievement and environmental values harmonize perfectly. Yet today, we all navigate systems designed for a bygone era of unlimited resources and minimal environmental consciousness.

Friday Biotech embodies what its name represents: turning constraints into freedom, protocols into creativity, and lab work into joy. Explore how our technology turns sustainability from obligation into inspiration.

"We cannot solve our problems with the same thinking we used when we created them." — Albert Einstein

About

Remember an era not so long ago? Friday used to mark the boundary between work and leisure, obligation and creativity. It was a weekday of lightness and joy when we shed our professional skins, diving into a brief break before the cycle reset on Monday. Trapped in the repetitive pattern of our lives, we sought comfort in our bubbles to flee from the many contradictions brought by the ever-fast-changing world.I dream of a world where every day feels like Friday, where telling children about our current reality like a relic. A world that transcends outdated concepts and our visions, where our lives and ideas resonate, creating meaningful connections in a world of increasing polarization. At Friday, we're not waiting for some far-off future to bridge these divides. We are here to build up a future, where the purpose of innovation is not only to disrupt, but to inspire and to include.FRIDAY Biotech, named after our vision of everyday inspiration, was found to develop sustainable, cost-effective solutions in cell culture technology that not only advance scientific research but also inspire a new way of thinking about biotechnology's role in society. From our innovative concept bioreactor to groundbreaking serum replacement technologies. We're not just creating products; we're cultivating a mindset. One where sustainability isn't just a buzzword, but a rhythm we dance to. Where innovation means everyone gets an invitation to the party of progress.Sounds too abstract? Discover how our innovation can transform your work and business - explore our solutions to join the revolution. :-)Be part of our Friday community - as friends, partners, customers, or investors. But most importantly, be Fridayers!Get in touch!Jianan Fu

Founder and CEO

Contact

Leopoldstrasse 31

80802 München

Germany[email protected]

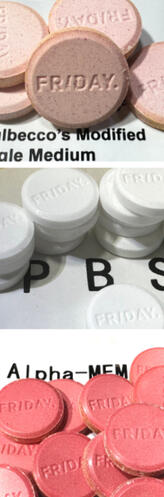

Cell Culture Media on Demand

Let's make cell culture simple, sustainable, and ready when you are. Turning tablets into fresh media in a few minutes. Cell Culture Media at the push of a Button. No cold chain. No plastic waste.

Pending patents

JUICI - Reinventing

cultivated food

A consortium by Friday and FBN (Leibniz Institute for Farm Animal Biology) to revolutionize cultivated fat.

From €25M Industrial Facilities to €250K Local Production - transforming cultivated meat from outdated industrial concept to sustainable reality

Made in Rostock, Germany, 2024

Cell Culture Media on Demand

Let's make cell culture simple, sustainable, and ready when you are. Turning tablets into fresh media in a few minutes. Cell Culture Media at the push of a Button. No cold chain. No plastic waste.

Pending patents

We question convenience in our daily lives - brewing coffee at home instead of buying takeouts, preparing meals rather than ordering delivery. Yet in our labs, we unquestioningly accept ready-to-use media as the only option. Why?

Traditional media solutions hide their true costs behind cold-chain logistics, storage infrastructure, waste management, and labor inefficiencies.

100+ million

liters of water are shipped around the world due to lack of alternatives

5,000+ tons

of plastic waste annually generated from pre-packaged liquid media

Massive energy

required for continuous cold chain maintenance during transport and storage of liquid media

Premium prices

inflatedby outsourcing the media preparation - paying $5 for a takeout that costs only $0.50 to make a coffee at home

Pending patents

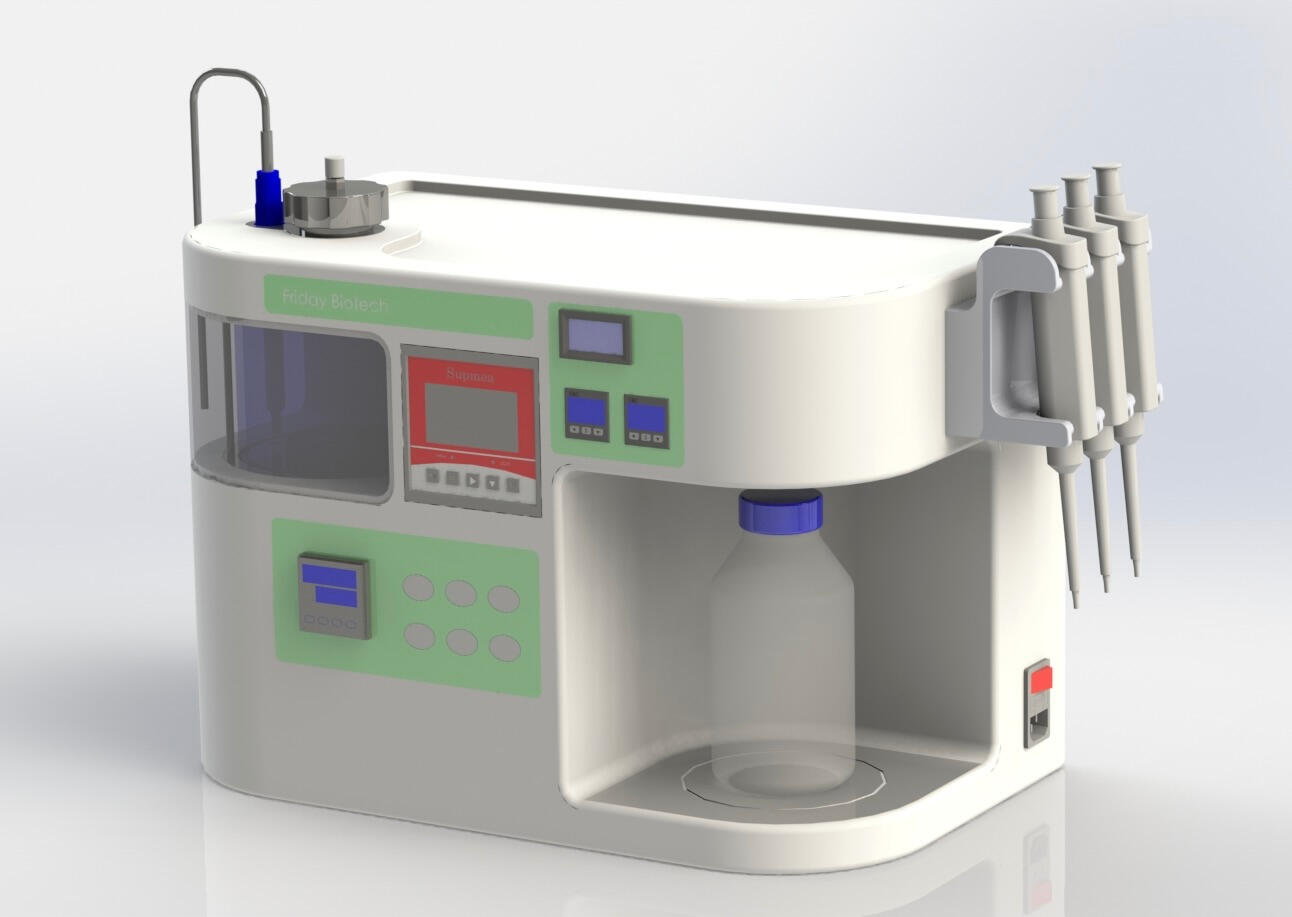

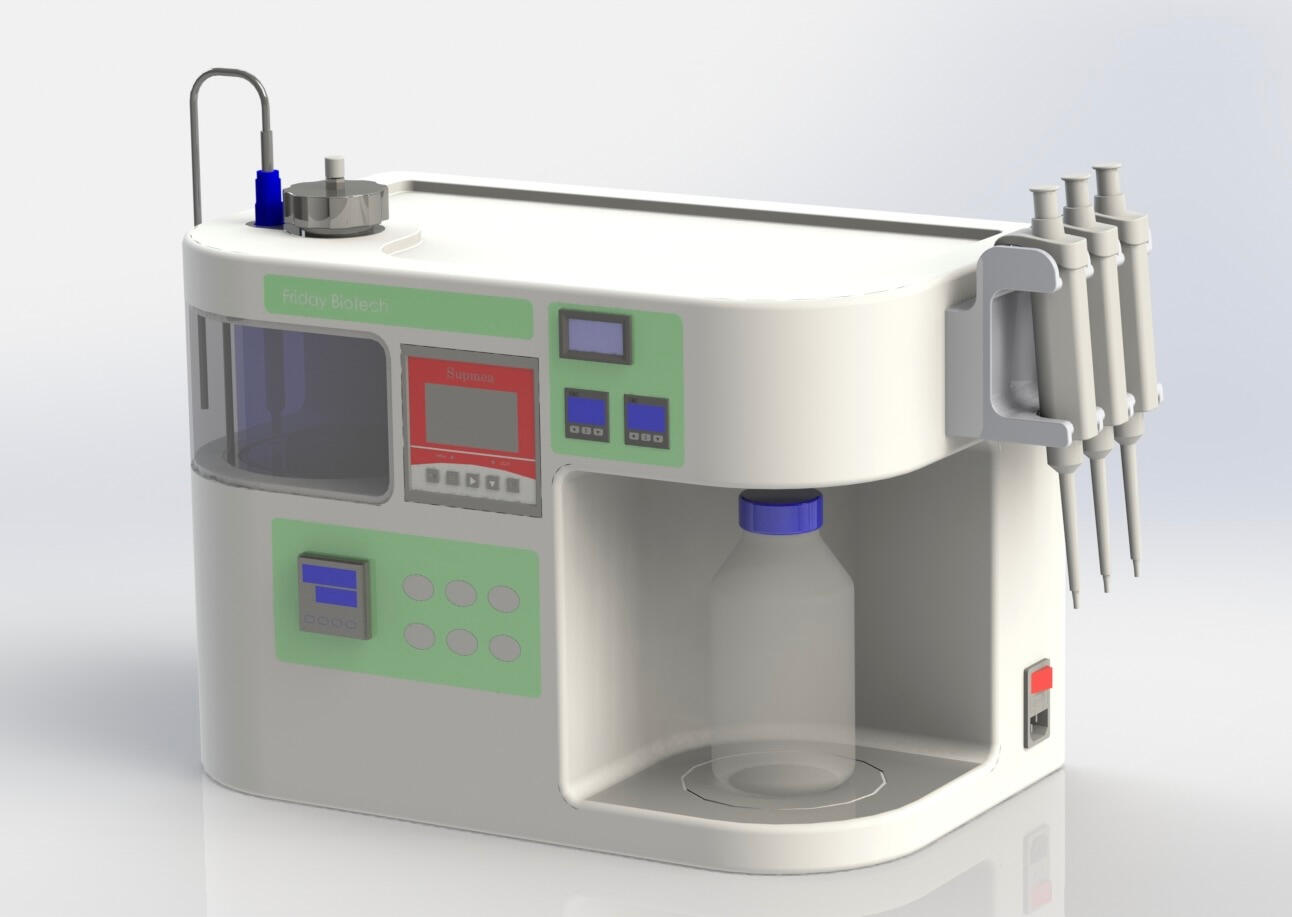

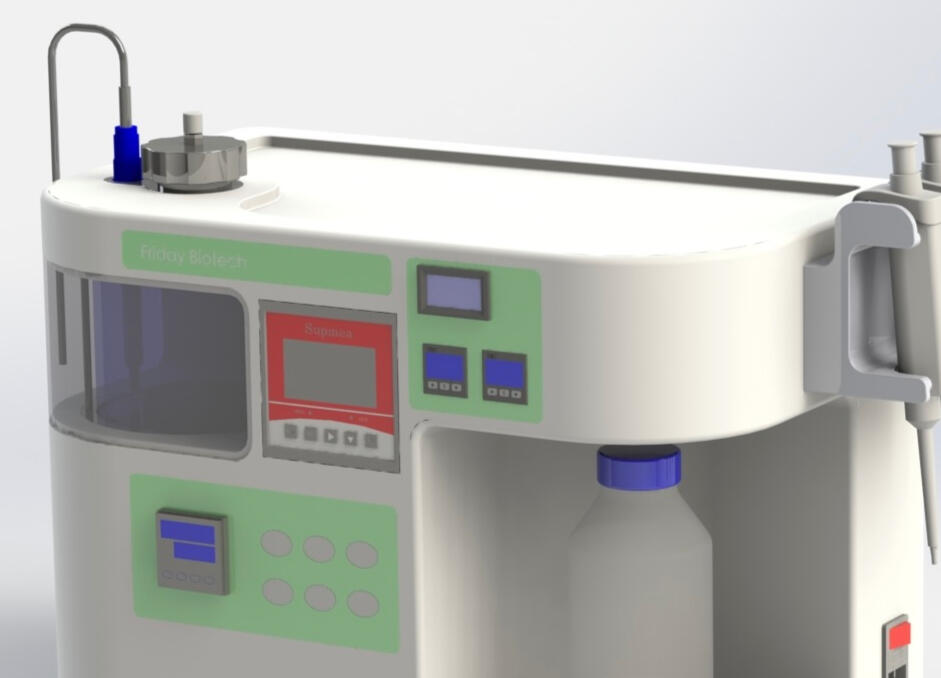

Media on Demand

Optimal media preparation through ultrasonic dissolution

Compact design enables operation both in and outside laminar flow cabinets

Real-time pH, temperature and pressure monitoring

Automated sterile filtration and dispensing for standard 500 mL volumes

Flexible volume > 300 mL via Luer Lock connection

Clean-in-Place system with stainless steel reusable filters

Sterilization conforming to European medical device sterilization standards

Media Tablets

Binder-free technology - 100% original formulation

Perfect dosing precision through tablets - simply count rather than weigh

Superior stability - our tablets resist moisture and oxidation where powders rapidly degrade

No dust contamination risks across workspaces and between batches

Optimized for ultrasonic processing

JUICI - Reinventing

cultivated food

A consortium by Friday and FBN (Leibniz Institute for Farm Animal Biology) to revolutionize cultivated fat.

From €25M Industrial Facilities to €250K Local Production - transforming cultivated meat from outdated industrial concept to sustainable reality

Made in Rostock, Germany, 2024

Is cultured meat sustainable?

The paradigm of the past 150 years - cost reduction and productivity above all - cannot solve the problems it created.

Since the Victorian era, industrial production has pursued a single path: centralize and intensify -regardless of environmental and social costs cellular agriculture offers breakthrough science trapped within this outdated industrial mindset.

$3+ Billion

invested in end-products built on fundamentally unsustainable infrastructure.

€25+ Million

facilities will be required through ever-larger bioreactors - an unproven and likely impossible path for complex stem cell cultures

Centralization

requires massive upfront capital and continues to disconnect food from communities

80%

of production costs tied to culture media reveals a devastating flaw in cultivated meat's foundation

Strategy

Media-on-Demand System - directly addresses 80% cost barrier; increases sustainable value and enables on-site media preparation to reduce cost.

Classic media from the 1950s were designed for research, not food production. We include regional agricultural raw materials, eliminating unnecessary pharmaceutical-grade components while creating sustainable local supply chains.

We're replacing costly and variable umbilical cord cell harvesting with stable, immortalized cell lines specifically engineered for fat production.

Simplified, process-dedicated bioreactors reduce capital requirements by 60-70% while decreasing operator training from months to days - democratizing production capability beyond specialized facilities.

Fat-First Approach - Cultivated fat delivers immediate value with simpler requirements than muscle tissue. This provides critical flavor components in meat alternatives while enabling faster market entry and earlier revenue generation.

Achieved

Cultivated fat tissue built on €2.3M CELLZERO BMBF-project breakthroughs

Binder-free media-tablets and media on demand platform - one drawer of tablets instead of a cold room of liquid media!

Core patents application filed; function verified; LOIs available

Next

Cell line development and process optimization for low-cost environments

Customer testing program and commercial launch

Process-dedicated media and bioreactor for decentralized MSC culture process

OUR VISION - FROM INDUSTRIAL FACILITIES TO CELLULAR KITCHENS

Growing Cells Where Food is Needed

Cutting plastic und water waste

Reducing supply chain vulnerabilities

Creating the mouthfeel consumers demand (Juicy = JUICI)

Last updated: 26.10.2025Friday Biotech operates [friday-botech.de] (the "Site"). This page informs you of our policies regarding the collection, use, and disclosure of Personal Information we receive from users of the Site.Information Collection and Use

While using our Site, we do not collect any personally identifiable information unless you voluntarily provide it to us (e.g., by contacting us via email).Log Data

Like many site operators, we collect information that your browser sends whenever you visit our Site ("Log Data"). This Log Data may include information such as your computer's Internet Protocol ("IP") address, browser type, browser version, the pages of our Site that you visit, the time and date of your visit, the time spent on those pages, and other statistics.Cookies

Cookies are files with a small amount of data, which may include an anonymous unique identifier. Cookies are sent to your browser from a web site and stored on your computer's hard drive. Our website does not use cookies for tracking or analytics purposes. We only use cookies that are necessary for the functioning of our website.Changes To This Privacy Policy

This Privacy Policy is effective as of [Insert Date] and will remain in effect except with respect to any changes in its provisions in the future, which will be in effect immediately after being posted on this page.We reserve the right to update or change our Privacy Policy at any time and you should check this Privacy Policy periodically. Your continued use of the Service after we post any modifications to the Privacy Policy on this page will constitute your acknowledgment of the modifications and your consent to abide and be bound by the modified Privacy Policy.Contact Us

If you have any questions about this Privacy Policy, please contact us at [email protected].